Scientist Janine Benyus, in her 1997 work Biomimicry: Innovation Inspired by Nature, invites us to reimagine material research and production methods by taking nature as a model. The natural world manufactures, calculates, performs chemistry experiments, builds structures, and designs high-performance systems and tools. Benyus encourages interdisciplinary collaborations between design and science so that we might mimic these incredible feats. Cradle to Cradle: Remaking the Way We Make Things, published five years later by designer and chemist duo William McDonough and Michael Braungart, highlights the importance of planning for the end of a product's life from the moment it is designed in order to eliminate the need for waste.

Inspired by the ecological thinking of these visionaries, today we will look at how to make an eggshell biocomposite.

Before COVID-19, we planned to create bio-tableware for Sympoïétiques, helping to re-envision the material needs of a conference. Our contribution was meant to reduce the ecological impact of the event as well as recover and value the waste. Cyclical_Matters came to fruition in the early days of the pandemic when we were forced to shift our research spaces from our labs and studios to our kitchens. This interdisciplinary project is led by three artists and designers with complementary know-how and is supported by the expertise of chemist Yves Gélinas, member of the chemistry and biochemistry department at Concordia University.

A little chemistry to start: eggshells are primarily composed of calcium carbonate (95%) but also contain proteins (3%) and water. For this recipe, powdered eggshells are incorporated into a viscous mixture of water and sodium alginate. Sodium alginate (C6H7NaO6) is a polymer derived from brown seaweed and is composed of carbon, sodium, hydrogen, and oxygen. It is a gelling and emulsifying agent primarily used in cooking and is classified as a food additive (E401). In the presence of calcium it allows for spherification, a chemical reaction that binds molecules, resulting in material agglomeration. Once the eggshells are thoroughly combined with the hydrated sodium alginate solution, pour them into a mould and cover them with vinegar. Adding vinegar to the calcium carbonate and sodium alginate mix is what causes the material to harden. At the molecular level, vinegar—an acid—mixes with the carbonate to form carbonic acid (H2CO3), which quickly decomposes into carbon dioxide and water (H2CO3 à CO2(g) + H2O). During the drying process, the water and carbon dioxide evaporate and the residual calcium, which is not volatile, acts as a binder that allows for the agglomeration of the alginate molecules.

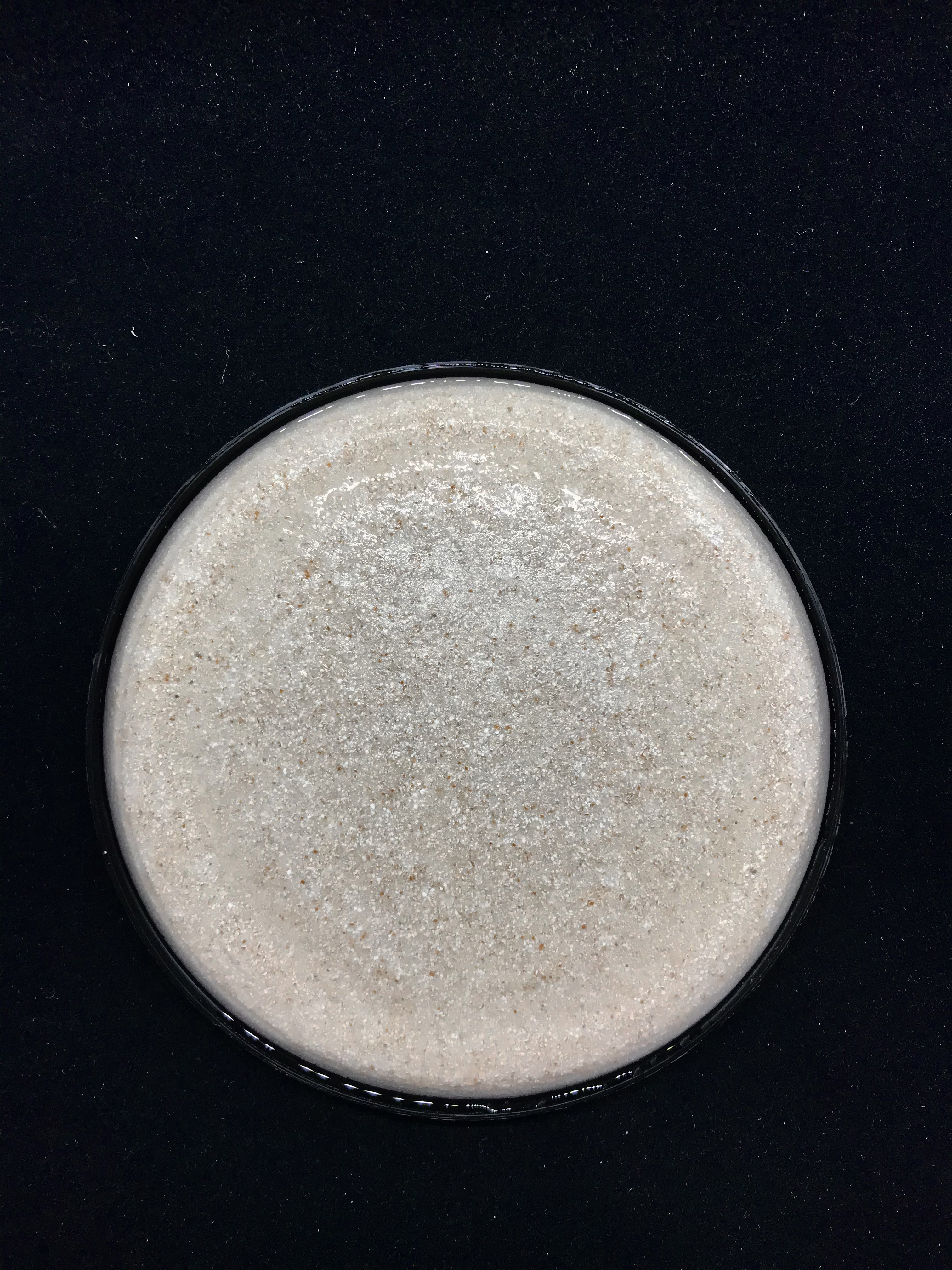

Fig 1: Semi-liquid biocomposite , covered with vinegar for 1 hour on each side.

Fig 1: Semi-liquid biocomposite , covered with vinegar for 1 hour on each side.

Here is what you need to create a ~10 cm diameter plate:

Tools and equipment:

- Kitchen or precision scale

- Blender

- Two ramekins or jars (one for the eggshell powder and the other for the alginate)

- Mixing spoon or spatula

- Yogurt lids (~10 cm in diameter) or silicone moulds

- Spray (for vinegar)

Safety: To avoid inhaling fine particles, it’s important to wear a mask when grinding and handling the eggshell powder. A surgical mask from the pharmacy (~$1 each) is more than sufficient because eggshell powder particles are larger than the droplets that spread viruses.

Ingredients:

- 15-45 mL vinegar (or enough to cover your mixture on both side)

- 45 g eggshell powder

- 200 mL water

- 4 g sodium alginate

Preparation:

- Collect eggshells (at home or from a restaurant).

- Clean and boil the shells for 15 minutes to remove bacteria.

- Fully dry them for 15 minutes in the oven at 100˚C / 212˚F (or lower for longer) to render them more brittle. You don’t want them to start browning.

- Grind the shells using a blender (or a mortar and pestle, if that’s what you have). *At this stage, wearing a mask is strongly recommended because the powder gives off a fine dust that can be easily inhaled*

- While still wearing the mask, pass the powder through a sieve. You will end up with two types of materials: fine and coarse powders, that will give you two different textures. ich remains.

- Keep your eggshell powders at room temperature in well-labeled jars.

- The day before you plan to make your biocomposite, prepare a 2% alginate solution with 200 mL of water and 4 g of sodium alginate (this is enough for several recipes).

Recipe:

- Mix 60 mL of hydrated sodium alginate with 45 g of eggshell powder.

- Lightly put one spray of vinegar on the bottom of your mould and spread it around with your finger (too much vinegar makes the mixture coagulate on contact and doesn’t result in even edges).

- Pour the mixture into the moulds (we generally use yogurt lids or silicone moulds) and spread it out. Depending on how thick your mixture is, you might be able to tilt your mould in order to fill it or you may need to use a spatula to push the mixture to the edges. Gently spray the top of it with approximately 15-20 mL of vinegar.

- After 30 mins, gently lift up the biocomposite edges to allow the vinegar to pass underneath and let it rest for an hour. Gently remove the biocomposite from the mould and rinse it under water. Place it in between two plates or the mould of your choice and in the oven at 55˚C / 130˚F for 30 mins (or the lowest temperature it will go). Remove from the oven, soak up the water that has separated from your composite, and return to the oven for 30 more mins. Finish by air-drying for 2-3 days.

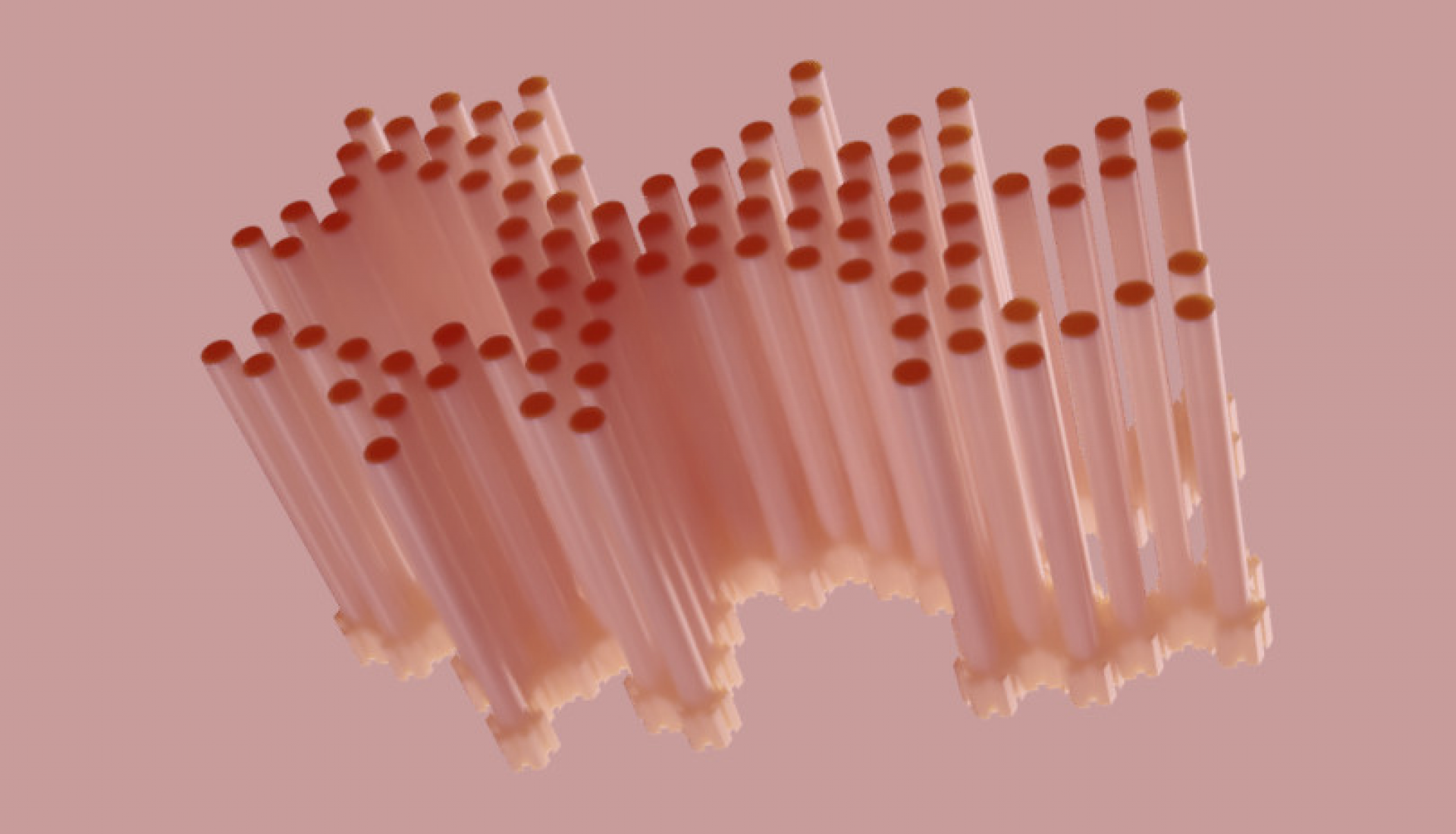

Fig 2: Irregular edges achieved by pouring more vinegar in the mold at first. Cool to experiment too :)

Fig 2: Irregular edges achieved by pouring more vinegar in the mold at first. Cool to experiment too :)

Our process is inspired by a recipe on materiom.org, an open-source site dedicated to fostering an international community of makers and researchers.

Your comments and questions will be welcome during our Live Cooking Show which will take place on October 20th, on the Sympoïétiques platform. Your personal experiments will allow our community to develop healthier and compostable materials in order to get rid of our dependence on oil and avoid leaving indelible traces on our planet and in our living organisms.

Have fun ! We can't wait to see your creations :)

References:

Benyus, J. M. (2002). Biomimicry : Innovation Inspired by Nature. HarperCollins Publishers Inc.

McDonough, W., & Braungart, M. (2002). Cradle to Cradle : Remaking the way we make things. North Point Press.